Heat pump dryers save the day

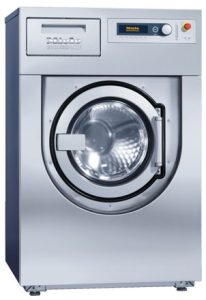

Stellisons Commercial supply St Michaels Homes Ltd. with three 13Kg washers (PW6137) and three 13Kg dryers (PT8337) – a state of the art laundry for the newly constructed Howards Lodge…

When St Michaels Homes Ltd set about the ambitious task of constructing Howards Lodge, a premium care facility tucked away in a sublime area of rural Brentwood, quality was always at the forefront of decision making.

Director Sean Watson desired a laundry which could not only handle the pressure of a 68 bed nursing home but also deliver outstanding wash performance and economy. Only the Miele Professional brand fitted this criteria, standing head and shoulders above the rest with regard to reliability, wash quality and low running costs.

Stellisons Ltd, Sean Watson’s local Miele Professional Partner servicing Essex and Suffolk was there every step of the way from planning and discussions with developers Baxter & King, to installation and staff training. Using our 52 years of experience we were able to assist St Michaels Homes and develop a laundry tailored to their specific needs.

From the outset it was decided such a project would require several large capacity machines. Through numerous consultations it was decided three 13Kg washers (PW6137) and three 13Kg dryers (PT8337) would create the ideal laundry.

However, due to planning restrictions the six chimneys required for the dryers installation were turned down by the local authorities. To overcome this barrier Stellisons introduced Sean Watson to Miele’s new range of heat pump driers. This provided the ideal solution, allowing the laundry to operate three PT8337WP heat pump dryers with only the addition of a window vent.

Choosing Miele’s heat pump dryers also provided the additional benefit of substantially reduced operating cost, saving 54% in electricity consumption per load (comparison made between a PT8337 gas dryer and a PT8337WP heat pump dryer).

Installing the appliances into Howards lodge’s 2nd floor laundry also presented another challenge. To overcome this Stellisons worked in close collaboration with specialist handling firm Stanley Handling. Within the first day the machines were positioned in the laundry room and each appliance could be connected by one of our qualified engineers to the utilities specified.

The final element of the installation was the fitting of chemical dosing pumps to each of the three washing machines. This enables each machine to take the precise amount of laundry liquid, helping to save money and reduce breakdowns.

Since our installation Howard Lodge is now in full operation delivering the very best standards of care for the elderly. Stellisons Ltd would like to wish Director Sean Watson and his team the very best for the future.

Approved Miele Partner 2024

Approved Miele Partner 2024